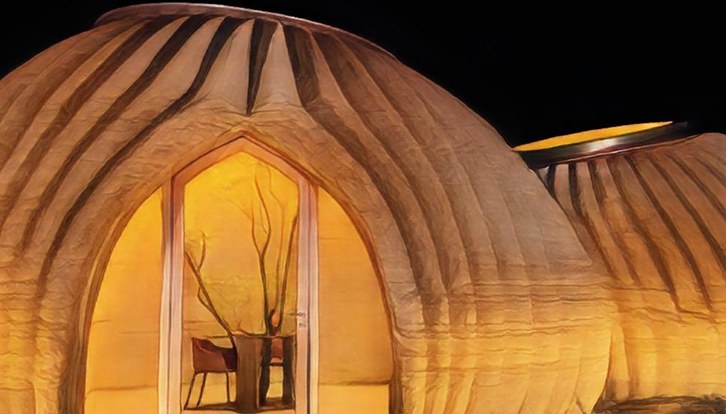

What you’re looking at are 3D-printed madhouses. Yes, houses printed by machines—and powered by Mac systems, no less. The process is as futuristic as it sounds: the desired design is entered into a computer, and the machine goes to work, literally printing the structure into existence.

These are structures built using large-scale 3D printers that extrude layers of earth-based materials—primarily clay, mud, or a mix of soil, water, and natural binders—to create walls and entire dwellings. The method mimics traditional rammed earth or adobe techniques but automates them for speed, consistency, and modern design possibilities

From Concrete to Clay: A Sustainable Shift

Initially, these futuristic homes were printed using concrete or cement. But there’s a growing shift toward using clay or mud, and for good reason. Builders believe clay is more sustainable and cost-effective, especially when compared to traditional materials. Ironically, this very technique—once rejected across parts of Africa—is now being hailed as a breakthrough in eco-friendly architecture.

Designed With Culture in Mind

One glance at the architectural style, and you’ll instantly recognize the cultural influence—no one needs to tell you where these designs originate. These homes are more than just functional; they are modern tributes to indigenous construction styles, deeply rooted in heritage.

Meet the Visionaries: Tekley Technology and Clea

The pioneering force behind this innovation? Tekley Technology and Clea. According to the team, “It’s possible to literally print a house from clay—a resource that’s everywhere and free.” Even more astonishing, the total cost of building such a house doesn’t exceed the price of an average iPhone.

Global Application, Local Materials

The company envisions this technology being used globally. Their goal? To print similar structures using regionally available materials, tailored to each environment. It’s an approach that marries cutting-edge tech with local sustainability.

Specs That Matter

Take their latest project: a 646-square-foot home standing 14 feet tall, complete with a living room, kitchen, and sleeping area. It’s compact, but functional—ideal for millions who need affordable housing without sacrificing basic amenities.

The Real Estate Disruption Ahead

Here’s the big picture: by 2030, nearly 4 billion people earning less than $3,000 per year will drive demand for ultra-affordable housing. Most of them won’t be able to spend more than 10% of their income on shelter. That’s where clay construction shines—with homes costing less than $1,000, this innovation could revolutionize the global real estate market.

Here is a little history on how long Africans have been using mud to build their homes.

Africans have been building homes with mud and clay for thousands of years—a practice dating back to at least 5000 BCE, and likely much earlier.

🏺 Historical Context

Ancient Egypt: Mudbrick (made of Nile silt, sand, straw, and water) was used extensively to build houses, walls, and even palaces and tombs. The practice dates to the Pre-dynastic Period (~5000 BCE).

Nok Civilization (Nigeria, ~1500 BCE – 500 CE): Evidence suggests the use of earth in constructing houses and furnaces.

Sahelian Architecture: In regions like Mali, Niger, and Burkina Faso, iconic mud structures—such as the Great Mosque of Djenné (originally built in the 13th century)—show a highly developed architectural tradition using sun-dried mud bricks (adobe).

Zulu, Ashanti, and others: Across Sub-Saharan Africa, many ethnic groups developed vernacular architecture using earth—clay, cow dung, and straw—to build circular huts and compounds with excellent thermal insulation.

🏡 Why Mud and Clay?

Abundant and local: Readily available in most regions.

Thermal comfort: Keeps interiors cool in the heat and warm in the cold.

Low cost and repairable: Easy to maintain and rebuild.

Culturally embedded: Designs, techniques, and symbolic decorations are often passed down through generations.

🌍 Modern Relevance

Despite urbanization, mud-clay building remains widespread in rural and semi-urban Africa today. New movements, including bio-architecture and sustainable design, are also reviving and celebrating these traditional practices.

Would you like a brief timeline or visual map of traditional mud-building regions in Africa?

🔧 How Does It Work?

Design Phase: Architects and engineers use software (like CAD) to design the structure.

Material Prep: A natural mix (usually clay-rich soil with fibers like straw or rice husks) is prepared to achieve the right consistency.

Printing: A robotic arm or gantry-style 3D printer deposits the material layer by layer to build walls—often without formwork.

Finishing: Once printed, walls dry naturally. Additional elements (roof, doors, insulation, etc.) may be added conventionally.

🌿 Why Use Clay or Mud?

Abundant and Local: Earth is available almost everywhere, reducing the need for transported materials.

Sustainable: Minimal CO₂ emissions compared to concrete; some variants are biodegradable.

Thermal Performance: Clay homes stay cooler in hot climates and retain warmth in cold ones.

Low Cost: Especially valuable for affordable housing and disaster recovery efforts.

🏠 Key Projects & Innovations

TECLA (Italy): A famous project by Mario Cucinella Architects and WASP, using locally sourced clay and printed using a crane-like 3D printer.

TOVA (Spain): A prototype home printed with clay and agricultural waste, fully biodegradable.

COBOD or ICON-type printers: Often adapted to print with earthen materials in rural or off-grid contexts.

⚠️ Challenges

Water Resistance: Pure mud or clay isn’t waterproof; must be treated or sheltered.

Regulations: Many countries lack building codes for earthen 3D printing.

Speed vs. Drying Time: Walls must dry properly to avoid cracking, which can slow the process.

Final Thought: Will Clay Homes Go Mainstream?

The question remains: Will clay 3D-printed homes become as popular as developers predict? If cost, sustainability, and cultural design are any indicators, the answer might just be a resounding yes.

Cmtv News News -Education – Entertainment – Sports

Cmtv News News -Education – Entertainment – Sports